Cotton is the most used material in our jersey products and the majority of it is organic cotton. We constantly strive to increase the proportion of recycled materials and, for example, recycled materials have been used in many of our products like The 3D Pantyhose, Dot styles and Bubble styles.

How do we handle chemicals in our sewing shop?

Because the jersey products are cut and sewn in our own sewing factory, no water or chemicals needed for dyeing and finishing are processed there, and the operation of our own sewing room does not cause waste water.

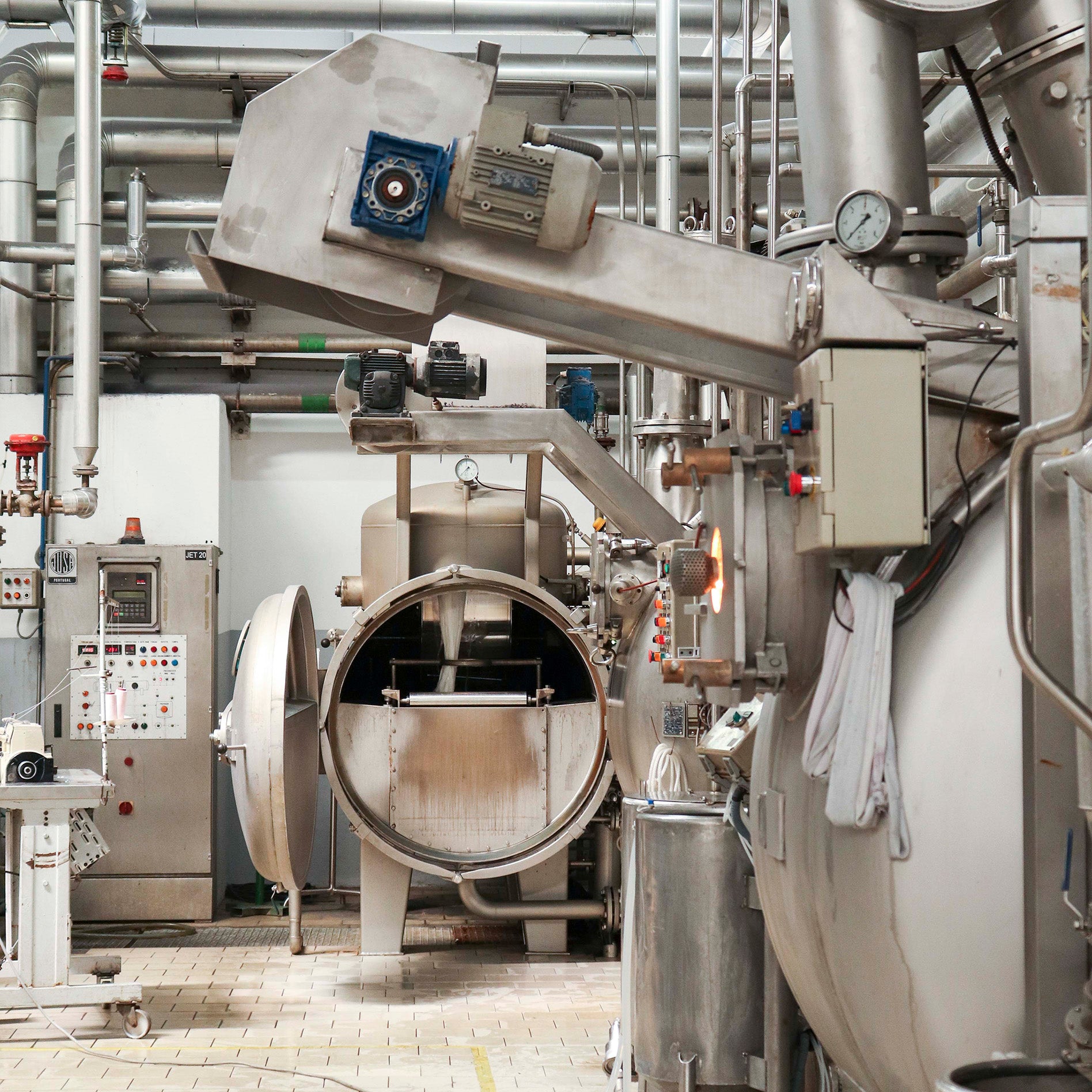

How does the dyehouse and printing house deal with chemicals?

The printing house that dyes and prints the fabrics for us has a statutory water treatment plant with a pH control system. At the Wastewater Treatment Plant, the water is pre-treated before being discharged into the City Wastewater Treatment Center. Color recipes are made by automation, so the loss of color chemicals is minimal. The dyes are treated in tubes so that they do not enter the respiratory tract.

In 2018, the printing house introduced Higg-Index, a toolkit developed by Sustainable Apparel Coalition that helps brands, retailers, and businesses of all sizes to measure and evaluate the sustainability of a company or product. The Higg Index enables companies to make significant improvements to the well-being of factory workers and local communities and to protect the environment.

In addition, the printing house is GOTS certified. GOTS (Global Organic Textile Standars) is an organization that promotes organic textiles and is the world’s leading certification system for organic textiles. GOTS defines high environmental criteria, covering the entire organic textile production chain from farm to cloth, and also requires compliance with social criteria. All processes in cotton production are approved by GOTS.

The printing house has been a Bluesign partner since 2012. This partnership ensures that only products and dyes that are properly tested and approved and that do not contain any substances that are harmful to humans or the environment are used in the dyeing and finishing process.

Where do our raw materials come from?

Cotton is our most important and most used raw material and most of it is organic. We use GOTS certified organic cotton purchased from Turkish cotton wholesalers. GOTS (Global Organic Textile Standards) is the world’s leading standard for the processing of organic fiber textiles.

Organic cotton fiber is further processed in northern Portugal, where it is spun into yarn or the yarn is already spun when it reaches Portugal. Basic yarns are usually spun in Turkey and specialty yarns such as custom and specialty blends are spun in Portugal. Dyed and printed fabric is then transported to our factory for storage, cutting and sewing. Production waste is recycled. Recycling is handled by Black Moda Portugal.

The wool we use in our knits is mainly mulesing-free merino wool and wool polyamide blended yarns. We use organic cotton and recycled polyester in our terry products. The “Bubble” series polyester is also recycled. Most of our woven products are linen and organic cotton.

What is our office in Finland like?

Aarrelabel premises are located in the same office as Black Moda Oy, where the energy we use is 100% renewable energy. The office also has waste collection: bio, plastic, metal, paper, cardboard and mixed waste. 4 people from Black Moda Oy's staff work on Aarrelabel productization and online store maintenance. Explore and contact us here.

Read more about our brand on the About page here.